IBM Maximo

Visual Inspection

Unleash the power of no-code computer vision for visual inspection automation

Overview

Empower your subject matter experts with automated visual inspection

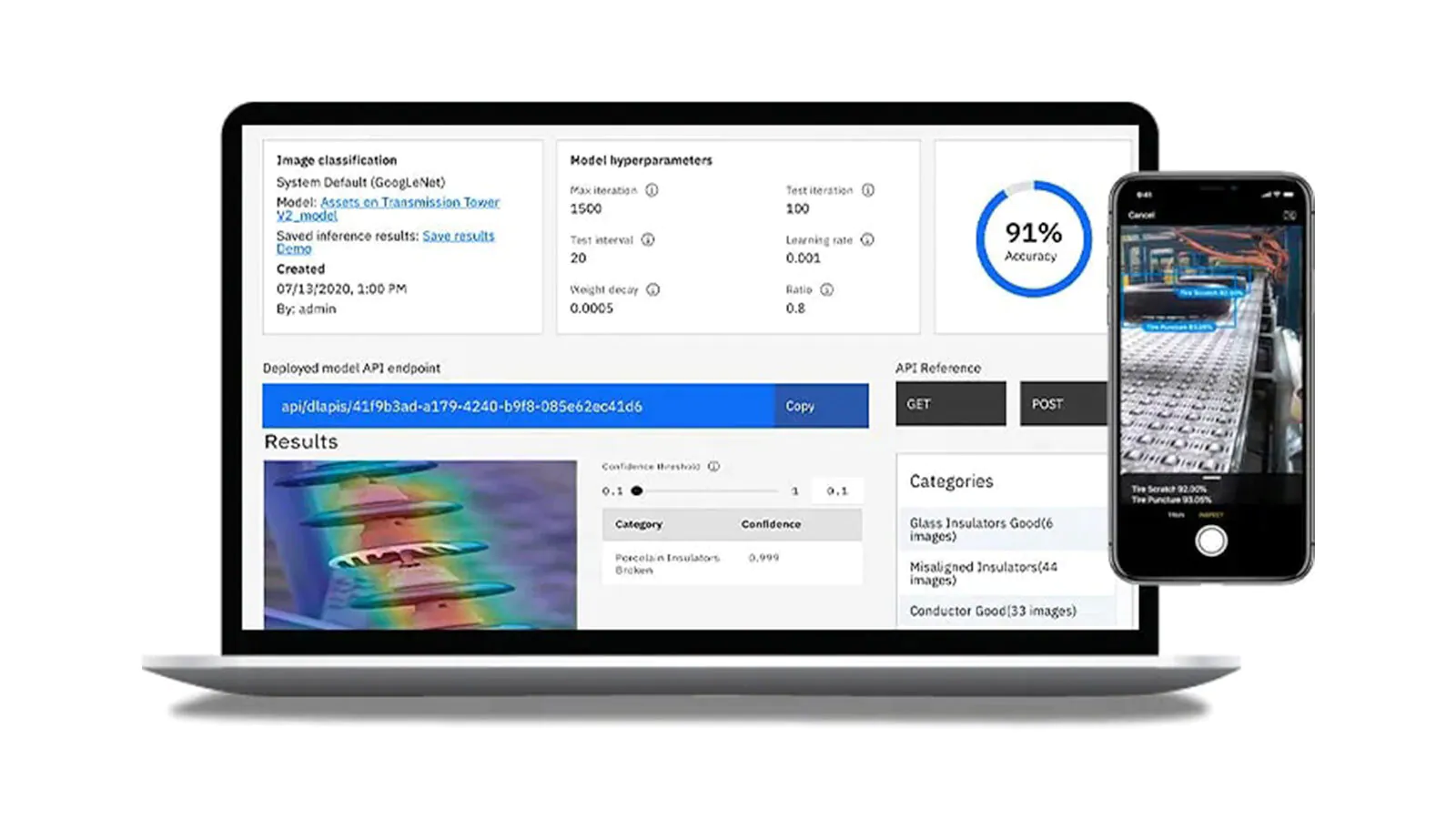

IBM Maximo Visual Inspection puts the power of computer vision AI capabilities into the hands of your quality control and inspection teams. It makes computer vision, deep learning, and automation more accessible to your technicians as it’s an intuitive toolset for labelling, training, and deploying artificial intelligence vision models. Built for easy and rapid deployment, simply train your model using our drag and drop visual user interface or import a custom model, and you’re ready to activate when and where you need it using mobile and edge devices. With IBM Maximo Visual Inspection, you can create your own detect and correct solution, with self-learning machine algorithms. Watch the demo below to understand how easy it is to automate your inspections processes with visual inspection tools.

Benefits

Accelerate defect detection

Continuously improve quality control through real-time end-to-end defect detection anywhere on the production line, support root cause analysis and boost manufacturing workflows.

Gain the flexibility to train and deploy anywhere

Simplify the process of gathering and labeling data sets, training models, and deploying those AI models at the edge.

Boost uptime with 24/7 real-time monitoring

Automate data labeling for deep-learning models to quickly spot and stop issues, alerting the right resource to inspect, diagnose and rectify any issue, anywhere.

Enable any subject matter expert (SME)

Provide SMEs the tools to codify their knowledge through an AI-powered visual inspection system that is fast and easy to create.

Increase worker safety through visual inspection software

Monitor and enforce inspection tasks and regulations for safety to protect workers from hazardous environments and dangerous conditions.

IBM Maximo Visual Inspection Edge

Visual inspection solutions

Scale quality control

The IBM Maximo Visual Inspection Edge suite interacts with IBM Maximo Visual Inspection (MVI) to deploy AI vision models to edge devices at scale. MVI Edge can be connected to multiple cameras including specialized high resolution cameras, drones and cameras on vehicles. The MVI Edge dashboard provides users the functionality to manage image analysis and view real-time inspections across multiple facilities or plants around the world. In addition, users can create inspection rules for defect detection.

IBM Maximo Visual Inspection Mobile

on iOS

Quality assurance for mobile

IBM Maximo Visual Inspection Mobile is a native iOS/iPadOS mobile app designed to enhance the capabilities of IBM Maximo Visual Inspection by rapidly scaling visual inspections to achieve lightning-fast ROI. Simply download MVI Mobile from the AppStore to run automated visual inspections at fixed locations or in the field. Maximo Visual Inspection Mobile delivers agility with point-and-click ease through the footprint of a mobile app while providing real-time, AI-powered inspection results. In a matter of hours, you can collect images from the mobile device to train complex computer vision models and deploy on the device to perform inferencing. The result is a dramatic improvement in production quality inspection and speed to help you detect defects and rework assets in the field.

Please enter your contact details.

Explore IBM Maximo

IBM Maximo Application Suite: Field service management

IBM Maximo Visual Inspection makes computer vision with deep learning more accessible to business users with an intuitive toolset that empowers anyone to label, train and deploy AI vision models.

IBM Maximo Application Suite: Mobile EAM

Connecting technicians with mobility and AI and deliver the right asset operational data and step-by-step guidance to technicians when and where they need it with AI-powered assistance.

IBM Maximo Application Suite: Remote asset monitoring

See, predict and prevent issues with advanced AI-powered remote asset monitoring and computer vision for assets and operations.