How smart manufacturing can optimize your factories for the new era

The focus of every industrial revolution has been increasing the productivity of production systems. The fourth industrial revolution is here, and it’s seeking to improve both production and management systems. Digital transformation driven by smart manufacturing (also known as Industry 4.0) is the basis of this latest one – creating opportunities to achieve levels of productivity and specialization not previously possible.

Combining data generated through the Industrial Internet of Things (IIoT) and analytics creates a new set of capabilities known as predictive maintenance and quality. Fueled by smart manufacturing, these new capabilities are changing the way we do and see business, helping recognizing patterns and predicting failures or product quality issues before they happen.

Are you on track to make smart manufacturing a priority?

The new industrial IoT platform

Most factories are composed of operation technology (OT) assets such as machines, equipment lines and robotic devices that aren’t always connected. The current trend is leaning toward smart manufacturing with a more IT-based factory floor to help save time, labor, cost and maintenance and upkeep. With OT and IT converging, the IIoT platform is emerging as a new, innovative concept for smart manufacturing with artificial intelligence (AI)-based technologies, including analytics, big data and cognitive manufacturing.

Smart manufacturing can spur a new surge of manufacturing productivity.

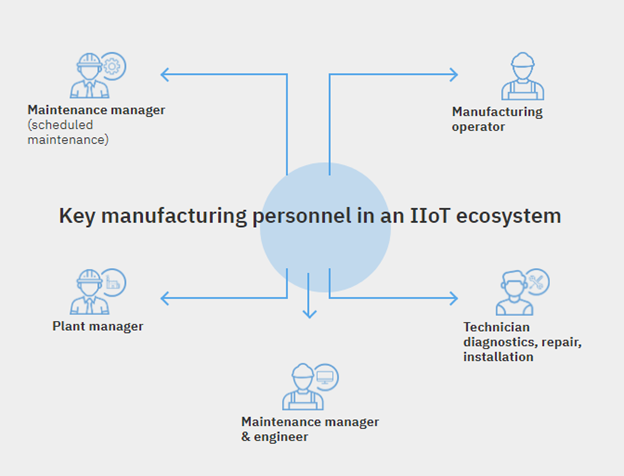

Targeting the pain points for key manufacturing personnel

In order to understand the impact of Industry 4.0 solutions, we must examine the key people involved in all aspects of a factory. True transformation happens when all unique challenges and each pain point is targeted.

Explore more about smart manufacturing ⇓

Please review and fill out your contact information to read the full white paper.

Images source: IBM